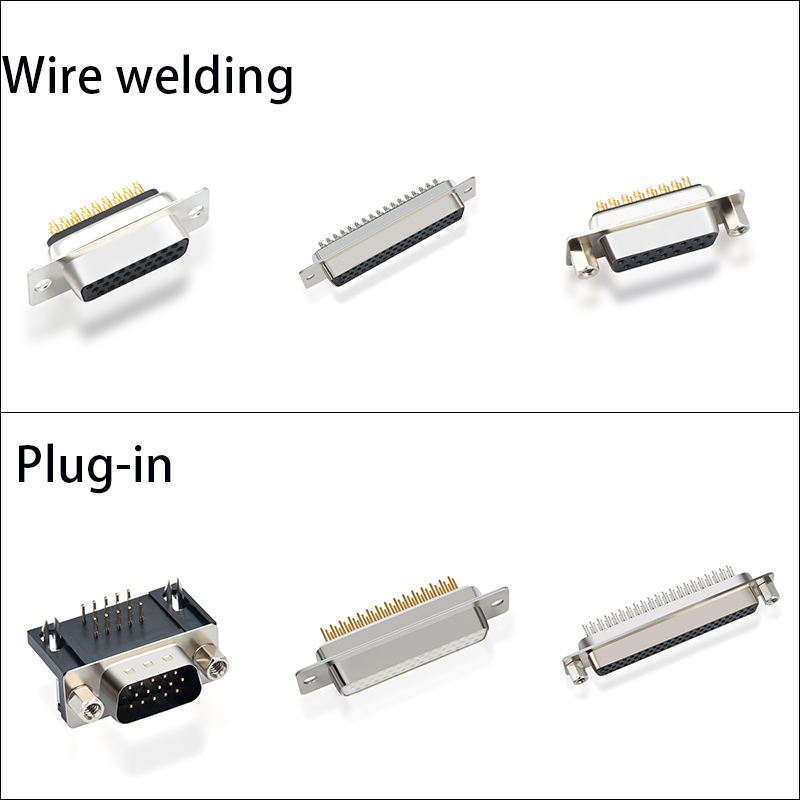

Connection method

D-SUB plug board series: usually connected by directly inserting the plug board into the corresponding socket or slot. The connection process is relatively simple and quick, without welding operation, strong pluggability, and convenient for installation, commissioning and disassembly and replacement during maintenance of the equipment.

D-SUB welding wire series: the wire is connected to the pin or terminal of the connector by welding. After welding, the connection is relatively firm and not easy to loosen, but the welding process requires certain techniques and tools, and once welding is completed, if it needs to be changed or repaired, it is relatively difficult to disassemble.

Electrical performance

D-SUB plug board series: because its connection method mainly relies on the contact between the metal pin and the socket, in the long-term use process, the contact resistance may gradually increase due to oxidation, wear and other factors, thereby affecting the signal transmission quality. However, under normal use conditions, general signal transmission requirements can usually be met.

D-SUB welding wire series: welding connection can provide a more stable and reliable electrical connection, reduce signal attenuation and interference caused by poor contact, and has certain advantages in transmitting large current and high-frequency signals, which can ensure the integrity and accuracy of the signal.

Mechanical strength and stability

D-SUB plug board series: The connection between the plug board and the socket mainly relies on the coordination of the mechanical structure. When subjected to external forces such as vibration and impact, it may become loose, have poor contact or even fall off, affecting the normal operation of the equipment. However, some plug board series connectors are equipped with locking devices to enhance the stability of the connection.

D-SUB solder wire series: The connection points after welding have high mechanical strength, can withstand a certain degree of external force pulling and vibration, are not prone to loosening or disconnection, and have better stability in some harsh working environments.

Applicable scenarios

D-SUB plug board series: Suitable for occasions that require frequent plugging and unplugging and high requirements for the maintainability and flexibility of the equipment, such as serial and parallel port connections of computers, as well as some temporary connections or test environments that require frequent equipment replacement.

D-SUB solder wire series: Commonly used in equipment that requires extremely high reliability and stability of electrical connections, such as industrial automation control systems, aerospace electronic equipment, military communication equipment, etc., as well as some occasions that require the transmission of large currents or high-frequency signals.