Do you know the application of D-sub connector?

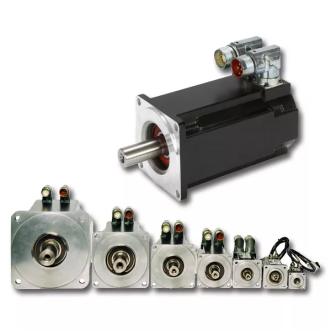

About D-sub Connector Applications – servo motor systems.

D-sub connectors are widely used, of which the industry with a huge amount is the servo motor system.

In general, the servo motor is actually part of the servo system. The servo system exchanges signals such as mechanical displacement, mechanical Angle, force, torque or acceleration according to the requirements of the control instructions. Systems for processing and power amplification. The electric servo system is composed of servo motor, feedback device, power drive device and controller. The motor is used as an executive element and a control element, and the mechanical parameters of the motor are used as a control object. Servo motor is the core of servo system, and its performance determines the final performance of servo system.

Servo motors can control speed and position with high precision, convert voltage signals into torque and speed control signals, and realize angular displacement or angular speed output on the motor shaft. The speed of the servo motor is controlled by the input signal and can respond quickly. In the automatic control system, the servo motor as the actuator has the characteristics of small electromechanical time constant, high linearity and low starting voltage.

Servo motor is divided into DC servo motor and AC servo motor.

According to the structure, DC servo motors are divided into two basic types: permanent magnets and electromagnets. Depending on the type, control method and rotor structure, it can be divided into many different motor types. If you are interested, you can search for it. One of the most typical is that there are more brush motors and brushless motors.

Ac servo motor according to the structure can also be divided into permanent magnet and electromagnetic two basic types. Depending on the electrical prototype, rotor structure and control mode, it can continue to be divided into many different motor types. Among them, the contact motor is relatively synchronous. Asynchronous motor.

The driving principle of servo motor: the servo is mainly positioned by the pulse. Basically, it is understood that when the servo motor receives a pulse, it will rotate the corresponding Angle of a pulse to achieve displacement. The servo motor itself has the function of transmitting pulses, so whenever the servo motor rotates at an Angle, a corresponding number of pulses will be issued, so that the system and the pulse of the servo motor interact to form a pulse. Closed loop allows system and motor pulses to be maintained. Synchronous, motor movement can also be precisely controlled by the system. The carrier of the pulse is usually the control voltage (or excitation voltage). Note: DC and AC servos are described separately in the general literature. After comparing several documents, this principle description is my personal understanding. If something is wrong, Hope you correct it.

The servo system is basically composed of a servo motor, a feedback device, a power drive device and a controller.

Feedback devices include: voltage sensors, current sensors, photoelectric encoders, magnetic encoders, Hall position sensors and temperature sensors, which are usually installed in the stator housing or winding of the servo motor.

The power drive device mainly provides the AC or DC drive power required by the main circuit or control circuit to the servo motor.

The function of the controller is to compare and analyze the signal obtained by the feedback device and output it. The signal is used as the control signal to realize the control of the power control driver. Typically, the power driver and controller are integrated in the servo driver.

With the development of intelligent manufacturing and robots, a variety of small servo motors have been applied to the market as drives. Connecting the drive from the control end requires a small size, large load, water resistance, temperature resistance, oil resistance of the small connector. Adam D-sub connectors As widely available above the servo drive connectors, we have absolute advantages:

- Screw activity is not easy to fall off, easy to install, good sealing.

- Special connector for servo motor.

- High waterproof rating IP67.

- Suitable for high temperature and high frequency vibration environment.

- Servo motor upgrade new connection scheme.