- D-Sub connector history

- D-SUB connector features

- lTechnical parameters of D-Sub connector

- lD-SUB connector application

- lWelding precautions for D-SUB connectors

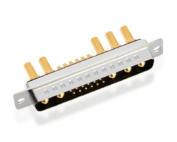

what is d-sub connector? The D-SUB connectors are designed to be a very economical interconnect solution to a variety of models , options and accessories . Include high and low frequency hybrid , high current and high density D-SUB connectors , D-SUB connectors , including insulator body , harpoon plate lock , back cover and multiple conductive terminal terminals ; assembled harpoons the plate lock is defined in the limiting mechanism , thereby effectively solving the problem that the existing D-SUB connector has different heights due to unreliable and easy rotation of the fishing fork plate .

D-Sub connector history

In 1982 (Inventive Module ) invented the industry’s first modular D-Sub connector socket . It began to be known as an innovator of communication cabling systems . Molex cabling developed historical wiring development history in 1983 . The concept of the D-Sub connector was developed from military connectors more than 40 years ago , and was subsequently widely used in commercial and military applications . The problem of screw-nut transfers when using cables has finally become a thing of the past .

D-SUB connector features

Different definitions of 25PIN D-sub connector signal to different modes : Computer parallel port Features of SHT10 The main features of SHT10 are as follows : Relative humidity and temperature measurement have dew point output . Features : structural standard , elegant appearance , easy installation , in line with a variety of standards . Column introduction : Professional D-SUB 15PIN plus iron shell connector column , check the latest D-SUB 15PIN plus iron shell connector market . D-SUB series and flat cable series connectors , etc . This series of products has reasonable design structure , complete varieties and reliable quality , and is widely praised by users all over the world . Features : Wide range of applications High quality , high reliability and protection .

Technical parameters of D-Sub connector

Technical parameters : The screw terminal block of the 37-pin D-type plug convert the 37-pin D-type plug on the I/O card into the corresponding screw ; the terminal connection size : 130mm X 78mm output connection , D-sub standard type welded plate rectangular connector Specifications : . DE-9PZ ; Product Category : Rectangular connectors . Main technical parameters : Working temperature : – 55 ~ 125 °C . Rated voltage : 300V

SUB connector application

The D-Sub connector is an industry standard connector for a wide range of NI C Series modules . For the most part , the difference in D-Sub attachments is only the number of pins in the connector . New economical connectors have been added to the D-SUB series . This new series is aimed at growing applications that require fewer plug-ins , such as set-top boxes , controls , and meters . FCI’s economical D-Sub connectors are designed to meet the needs of fewer plug-in cycle . Such as set-top boxes , control equipment and energy meters ; and the demand for such applications is getting higher and higher . The circuit board is directly welded economic series . The D-Sub connector is one of the earliest solutions and the most versatile and widely used input/output connector system . D-Sub connectors have remained almost unchanged over the past 30 years , and are now undergoing a revolution in D-Sub connectors .

Welding precautions for D-SUB connectors

(1) It is recommended to coat the inner mold with a layer of heat-insulating adhesive paper to prevent the core wire from being burnt when welding copper foil or injection molding;

(2) The coated copper foil is not allowed to be slit or damaged;

(3) If the copper foil is found to be damaged, the damaged portion may be covered with copper foil, and then the joint between the copper foil and the original copper foil shall be completely welded with solder;

(4) After completely wrapping the copper foil, it is not allowed to see the inner mold or the core wire exposed from any angle;

(5) When soldering, be careful not to burn the core wire.

(6) The phenomenon that solder is dissolved into the gap between the inner mold and the connector and the heat-insulating adhesive paper in which the solder penetrates into the inner mold is not allowed.

ADAMICU is a professional manufacturer of d-sub connectors. We have the most complete range of machine pin d-sub connector. Welcome to contact us. We offer the most sincere service. Contact us right now: Sales@adamicu.com